Why Your New Appliances Are Breaking Down So Fast: The Coquitlam Installation and Setup Mistakes That Void Warranties and Shorten Appliance Life

Frustrated with your brand-new dishwasher leaking after just six months or your expensive refrigerator making strange noises before its first birthday? You’re not alone – installation errors actually cause more warranty voidances than actual product defects, leaving Coquitlam homeowners stuck with expensive repair bills on appliances that should still be under warranty.

Picture this: you just dropped five grand on a gorgeous stainless steel kitchen suite, feeling like you’ve finally upgraded your home to match your Pinterest dreams. Fast forward eight months, and you’re staring at a puddle under your dishwasher while your refrigerator sounds like it’s hosting a death metal concert. When you call for warranty service, you discover that improper installation has voided your coverage entirely. This nightmare scenario plays out daily in Coquitlam homes, where the unique challenges of our mixed housing stock – from heritage character homes in Maillardville to sleek new condos in City Centre – create installation pitfalls that manufacturers love to exploit.

The truth is, modern appliances aren’t built like the workhorses our parents relied on for decades. While that avocado-green refrigerator from 1975 chugged along faithfully until it became a design embarrassment, today’s smart appliances are packed with complex electronics, cheaper materials, and planned obsolescence strategies that practically guarantee shorter lifespans. But here’s what appliance companies don’t want you to know: installation mistakes are accelerating these failures and giving manufacturers the perfect excuse to deny warranty claims.

In Coquitlam’s diverse housing market, where century-old character homes sit alongside ultra-modern developments, installation challenges multiply exponentially. Your gorgeous heritage home might have electrical systems that predate modern appliance requirements, while your new condo’s strata regulations could create compliance nightmares that void warranties even when everything seems to work perfectly.

Key Outtakes:

- Installation errors cause more warranty voidances than actual product defects, with improper electrical connections and inadequate ventilation leading the list of coverage-killing mistakes

- Modern appliances break down faster due to cheaper plastic components, complex electronics, and planned obsolescence strategies that replace durable materials with failure-prone alternatives

- Coquitlam’s mixed housing stock creates unique installation challenges where heritage homes need electrical updates and condos face strata regulations that complicate warranty compliance

- Professional installation documentation is crucial for warranty protection and prevents cascading financial impacts on insurance coverage and home values

- DIY installation attempts void manufacturer warranties more frequently than product defects, making professional setup a critical investment protection strategy

The Shocking Truth About Modern Appliance Failures

Walking through any appliance showroom today feels like stepping into a sci-fi movie – touchscreens everywhere, WiFi connectivity, apps that let you preheat your oven from the grocery store. But behind all that flashy technology lies a disturbing reality that manufacturers would rather keep quiet. Unlike older models, new appliances rely heavily on electronic components, which are more sensitive and prone to failure than the mechanical systems they replaced. Your grandmother’s washing machine had maybe three moving parts and could be fixed with a screwdriver and some elbow grease.

Today’s “smart” washing machines come packed with multiple circuit boards, sensors, and digital interfaces that create dozens of potential failure points. When I started repairing appliances twenty years ago, most problems were mechanical – a belt here, a motor there. Now, a single faulty circuit board can render an entire appliance useless and cost more to replace than buying a new machine. This shift from mechanical to electronic systems hasn’t just changed how appliances work; it’s fundamentally altered their lifespan expectations and repair economics.

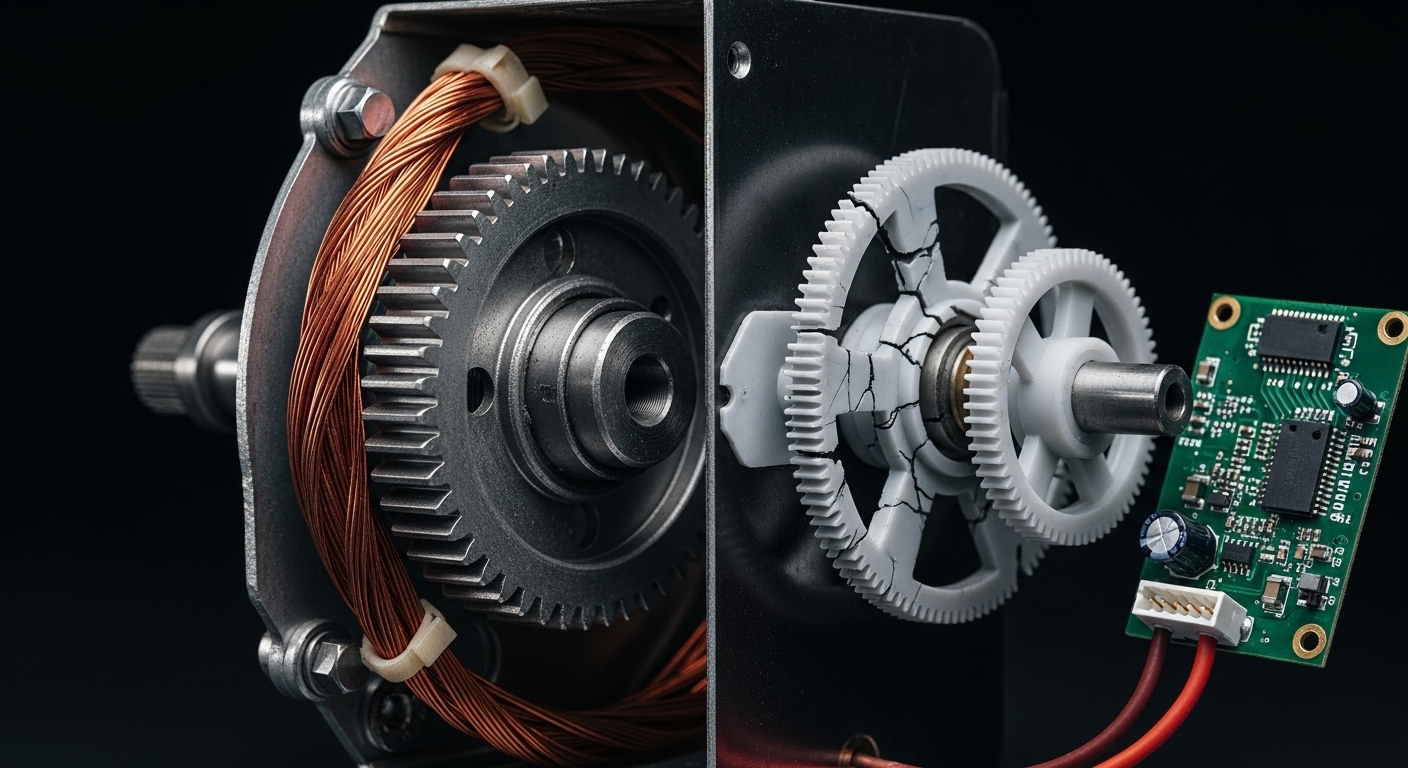

The materials story gets even more frustrating when you peek behind those sleek exterior panels. Many manufacturers now use cheaper materials to reduce production costs, with plastic parts replacing the metal components that made older appliances virtually indestructible. Where previous generations of appliances featured heavy-duty steel frames, copper components, and solid metal gears, modern units rely on lightweight aluminum, thin plastics, and composite materials that simply can’t withstand the same wear and tear.

This isn’t accidental – it’s a carefully orchestrated strategy called planned obsolescence. Manufacturers deliberately use plastic gears instead of metal ones, lightweight wiring that degrades faster, and components that are glued rather than screwed together. They’ve discovered that making appliances last forever isn’t a sustainable business model when they need customers to return every few years. The result is appliances that might look more sophisticated but are essentially designed to fail, usually just after their warranty periods expire.

Energy efficiency regulations have created an additional layer of durability compromise that most homeowners don’t realize. To meet strict environmental standards, manufacturers have had to use thinner insulation, weaker motors, and more complex systems that achieve better energy ratings at the expense of longevity. Your energy-efficient dishwasher might save you a few dollars on utilities, but its lightweight construction and sensitive electronics make it far more vulnerable to failure than the energy-guzzling workhorse it replaced.

Installation Nightmares That Instantly Kill Your Warranty

Here’s where things get really expensive for Coquitlam homeowners. While manufacturers happily tout their generous warranty coverage during the sales process, they’ve become incredibly sophisticated at finding installation-related reasons to deny claims when things go wrong. Installation errors now cause more warranty voidances than actual product defects, according to industry data that most consumers never see. What looks like a product failure to you becomes an installation issue to them, shifting repair costs back onto your shoulders.

Electrical connection errors top the list of warranty-voiding mistakes, and they’re surprisingly easy to make. GFCI protection requirements are frequently overlooked by DIY installers, immediately voiding manufacturer warranties even when the appliance appears to function normally. Using the wrong gauge wire for high-amperage appliances or failing to install proper disconnect switches creates safety hazards that manufacturers use to deny coverage. In Coquitlam’s older neighborhoods, where homes built before 1970 might have electrical systems that violate current codes, these issues become even more complex and expensive to resolve.

Ventilation failures create another massive category of warranty voidances that catch homeowners off guard. Over-the-range microwaves mounted just an inch too low cause overheating issues that manufacturers specifically exclude from warranty coverage. Refrigerators enclosed in beautiful custom cabinetry without adequate airflow force compressors to work overtime, leading to premature failure that gets blamed on installation rather than design. Even something as simple as failing to clean dryer vents – which causes more home fires than most people realize – can void warranty coverage when lint buildup leads to overheating damage.

The documentation game has become particularly ruthless in recent years. Professional installers provide detailed installation records, compliance certifications, and test results that manufacturers increasingly require for warranty claims. They photograph their work, document electrical measurements, and provide certificates proving code compliance – paperwork that DIY installers rarely think to create. When your appliance fails and you can’t produce this documentation, manufacturers have the perfect excuse to deny coverage, leaving you stuck with repair bills that can reach thousands of dollars.

Registration deadlines add another layer of warranty complexity that trips up well-meaning homeowners. Manufacturers typically require warranty registration within 30-90 days of installation, but the fine print often specifies that professional installation must be documented as part of the registration process. Miss this deadline or fail to provide proper installation documentation, and your warranty becomes worthless regardless of when or why your appliance fails. It’s a system designed to favor manufacturers while placing impossible burdens on ordinary homeowners.

Coquitlam’s Housing Challenge: When Your Home Works Against You

Living in Coquitlam means navigating one of Metro Vancouver’s most diverse housing landscapes, and that diversity creates unique appliance installation challenges that can void warranties in ways that catch homeowners completely off-guard. The transition from mechanical to electronic appliances affects every home differently depending on its age, electrical system, and compliance with current building codes.

Heritage homes built before 1970 present the most complex installation scenarios because their electrical systems often can’t safely support modern appliances without significant updates. These charming character homes might have adequate power for basic needs, but high-amperage appliances like induction cooktops or large refrigerators require dedicated circuits with specific amperage ratings that older wiring simply can’t provide. Attempting to install new appliances on inadequate electrical systems creates fire hazards and immediately voids warranty coverage, but the electrical updates required can cost thousands of dollars before you even plug in your new dishwasher.