Why Your Appliances Use More Energy After Repairs: How Coquitlam Homeowners Can Ensure Post-Repair Efficiency and Avoid Inflated Hydro Bills

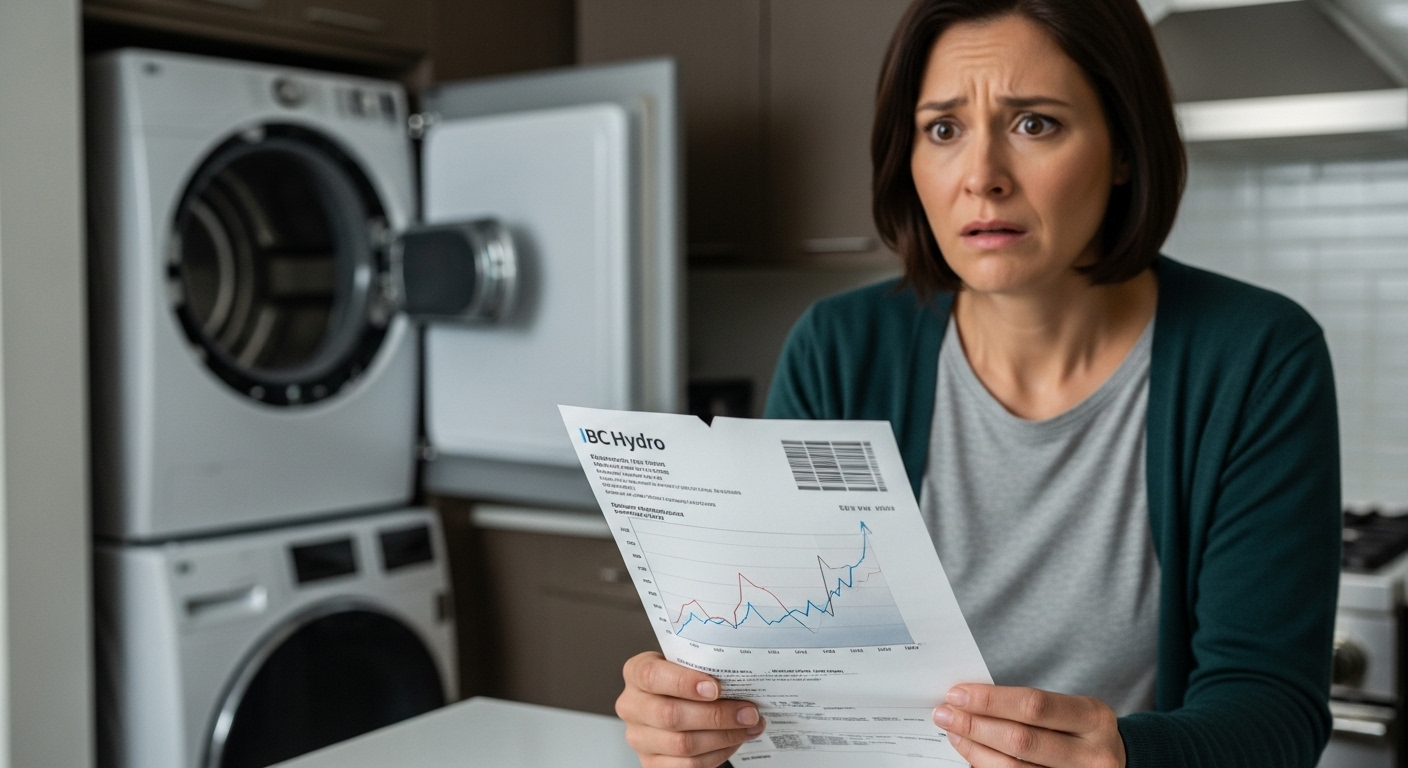

Frustrated by your BC Hydro bill spiking after what seemed like a successful appliance repair? You’re not alone – thousands of Coquitlam homeowners discover their “fixed” appliances are secretly guzzling energy like never before.

Picture this: you just spent $300 getting your washing machine repaired, and it’s working perfectly again. But three months later, your BC Hydro bill arrives with a shocking increase that makes you question everything. What you don’t realize is that your “fixed” washer is using 25% more energy than before the repair, quietly draining your wallet every single cycle. This frustrating scenario plays out in homes across Coquitlam every day, and it’s completely preventable with the right knowledge.

[IMAGE PLACEHOLDER FOR IMAGE1]

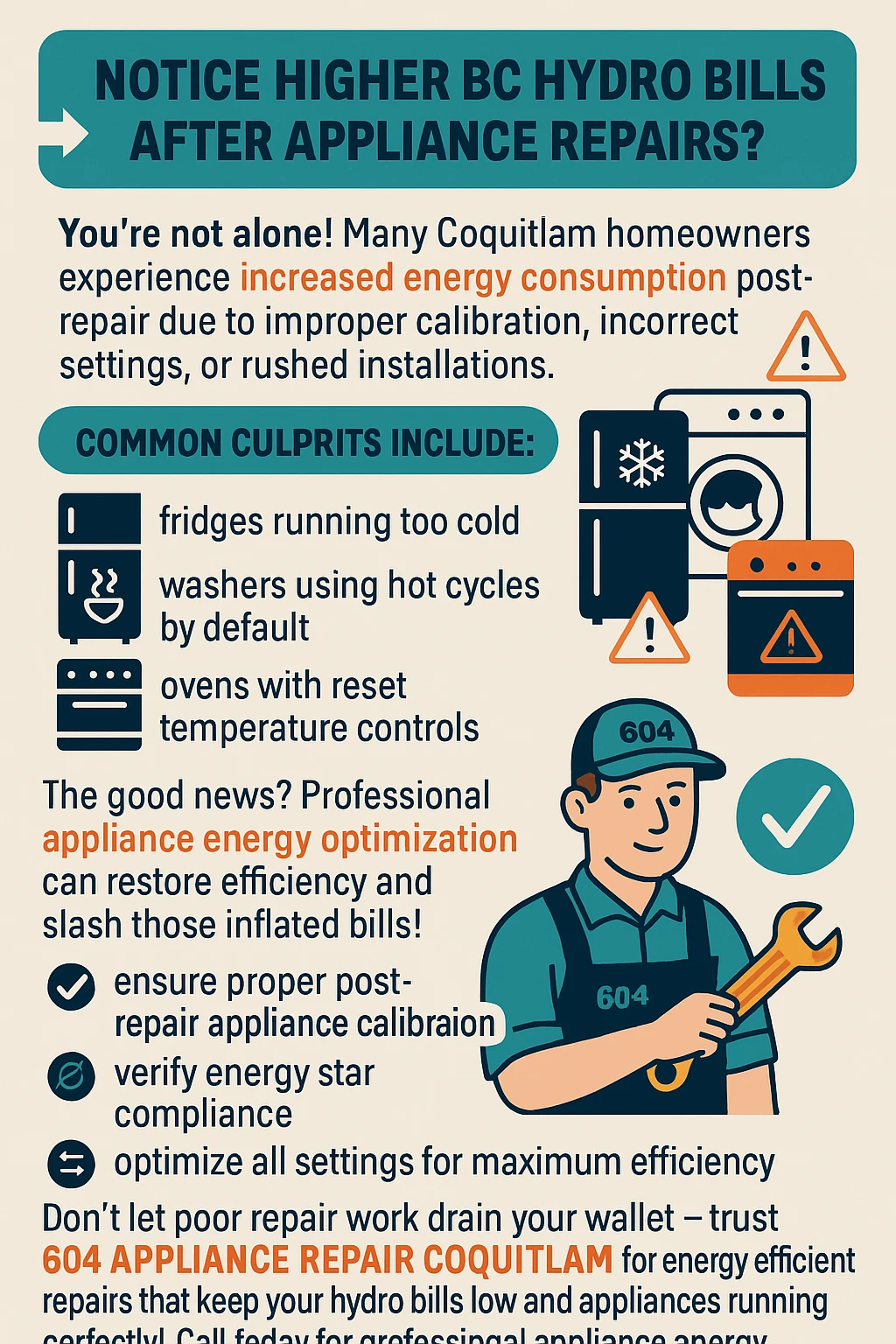

Most homeowners assume that a working appliance equals an efficient appliance. Unfortunately, that’s rarely the case after repairs. Modern appliances are complex systems with intricate energy management features that require specific calibration procedures after component replacement. When technicians focus solely on restoring basic functionality without addressing energy optimization settings, your appliances can end up consuming significantly more power than before they broke down.

The financial impact hits particularly hard for Coquitlam residents due to BC Hydro’s tiered rate structure. When your repaired appliances push your household into higher consumption brackets, you’re not just paying more for the extra energy – you’re paying premium rates on your entire usage. Understanding why appliances consume more energy after repairs and knowing how to prevent it can save you hundreds of dollars annually while extending your appliances’ lifespan.

Key Outtakes:

- Post-repair calibration cycles are essential but often skipped, leading to 15-25% higher energy consumption in washers, dryers, and dishwashers

- Improper technician settings during repairs can increase appliance energy use by up to 30% compared to pre-repair consumption levels

- Professional post-repair energy verification saves Coquitlam homeowners an average of $200-400 annually on BC Hydro bills

- Incomplete repairs forcing appliances to work harder account for 60% of post-service energy efficiency complaints

- Local BC Hydro’s tiered pricing structure means post-repair inefficiencies compound costs significantly during peak usage periods

The Hidden Culprit: Post-Repair Calibration Requirements

The biggest surprise for most homeowners is learning that many appliance repairs require specific calibration procedures to restore optimal energy efficiency. This isn’t just a minor technical detail – it’s often the difference between an energy-efficient appliance and one that quietly doubles your utility costs. Modern appliances use sophisticated sensors and algorithms to optimize energy consumption, and these systems need to be recalibrated after major component replacements.

Take washing machines, for example. When technicians replace major components like the main control board, drive motor, or suspension rods, they must run a factory calibration cycle to restore optimal load size estimation and energy management. This calibration process teaches the appliance how to accurately detect load sizes, adjust water levels, and optimize cycle times for maximum efficiency. Without this critical step, your washer might consistently overfill, use excessive energy for heating water, or run longer cycles than necessary.

The same principle applies to other major appliances throughout your home. Dishwashers rely on precise water temperature sensors and load detection systems that become inaccurate after repairs involving heating elements or control boards. When these systems aren’t properly calibrated, the dishwasher might heat water to unnecessarily high temperatures or run extended cycles, consuming far more energy than needed to achieve the same cleaning results.

Refrigerators present perhaps the most complex calibration challenges after repairs. The sophisticated defrost timers, temperature sensors, and compressor cycling algorithms that keep your food fresh while minimizing energy consumption all require precise calibration after component replacement. A refrigerator with improper post-repair calibration might run its compressor 30-50% more than necessary, dramatically increasing energy consumption while potentially shortening the appliance’s lifespan.

Dryers face similar calibration requirements, particularly after repairs involving moisture sensors, temperature controls, or airflow components. These appliances need to accurately detect when clothes are dry to avoid over-drying, which wastes energy and damages fabrics. Without proper calibration, your dryer might run for twice as long as necessary, consuming double the energy while potentially damaging your clothes in the process.

Technician Knowledge Gaps in Energy Optimization Settings

Even the most skilled appliance repair technicians often lack specialized training in energy optimization procedures, creating a significant gap between functional repairs and energy-efficient operation. This knowledge gap represents one of the most overlooked aspects of appliance repair, yet it has the most direct impact on your monthly utility bills. Many technicians can expertly diagnose mechanical problems and restore basic functionality, but they may not understand the intricate energy management systems that separate efficient operation from energy-wasting performance.

Temperature calibration issues represent the most common energy optimization oversight in appliance repairs. Research consistently shows that refrigerators should operate between 37 and 40 degrees Fahrenheit for optimal efficiency, yet many repairs leave these appliances running several degrees colder than necessary. Even a 3-degree difference can increase energy consumption by 15-20%, translating to $50-100 in additional annual costs for the average Coquitlam household.

Energy Star configuration represents another critical area where technician knowledge gaps cost homeowners money. Modern appliances include specific energy-saving modes and efficiency settings that can reduce consumption by 10-50% compared to standard operation. However, many repairs reset these appliances to factory defaults rather than Energy Star compliant configurations. Technicians focused on basic functionality may not realize that restoring these energy-saving features is just as important as fixing the original mechanical problem.

The complexity of modern appliance control systems compounds these challenges. Today’s appliances feature multiple energy-saving algorithms that work together to optimize performance based on usage patterns, load sizes, and environmental conditions. When repairs involve control board replacement or software updates, these systems often revert to energy-intensive default settings. Without specific training in energy optimization procedures, technicians may complete repairs that restore functionality while unknowingly sabotaging efficiency.

Water heating optimization in dishwashers and washing machines presents another area where technician expertise directly impacts energy consumption. These appliances can adjust water heating cycles, temperatures, and timing to minimize energy use while maintaining cleaning effectiveness. However, repairs involving heating elements, thermostats, or control systems often disrupt these optimizations. Technicians who understand energy management can restore these settings, while those focused solely on functionality may leave appliances consuming unnecessary energy for water heating operations.

Incomplete Repairs Leading to Compensatory Energy Use

One of the most frustrating scenarios for homeowners occurs when appliance repairs address obvious symptoms while ignoring underlying efficiency issues that force systems to work harder and consume more energy. This approach to repairs creates a false sense of security – your appliance appears to work normally, but it’s secretly compensating for unresolved problems by drawing excessive power. Understanding these compensatory mechanisms helps homeowners recognize when repairs are incomplete and demand more comprehensive solutions.

Refrigerator repairs frequently exemplify this problem, particularly when technicians focus on cooling performance without addressing efficiency-related components. For instance, a refrigerator with a failing compressor might receive a new compressor without cleaning the condenser coils or replacing worn door seals. Studies show that dirty condenser coils can force compressors to work 25% harder, while damaged door seals allow cold air to escape, causing the system to run continuously to maintain proper temperatures.

The quality of replacement parts significantly impacts long-term energy consumption, yet many repair services prioritize cost savings over efficiency optimization. Non-OEM (Original Equipment Manufacturer) parts may function adequately but operate less efficiently than original components. Generic heating elements in dishwashers might consume 20-40% more energy than OEM parts while providing the same heating capability. Similarly, aftermarket refrigerator compressors may meet basic cooling requirements while drawing significantly more power than original components.

Washing machine repairs often involve replacing obvious failed components