Wondering why your expensive appliances keep mysteriously breaking down despite proper maintenance during BC’s wet season? The combination of persistent coastal humidity, salt air infiltration, and freeze-thaw cycles is systematically destroying household equipment throughout Coquitlam and the Lower Mainland in ways that most homeowners never anticipate until repair bills start mounting.

Living in beautiful Coquitlam means enjoying stunning mountain views and mild coastal weather, but it also means dealing with environmental conditions that can be brutal on your most essential household appliances. The same moisture-laden air that keeps our region lush and green is simultaneously infiltrating your home’s equipment, creating corrosion, promoting mold growth, and causing electrical failures that often manifest as mysterious performance issues long before any visible damage becomes apparent.

What makes BC’s coastal climate particularly challenging for appliances is the unique combination of environmental stressors that work together to accelerate equipment deterioration. Unlike prairie cities with consistent cold winters or desert locations with predictable dry heat, our region subjects appliances to constant humidity fluctuations, salt air penetration, and temperature swings that manufacturers rarely account for in their design specifications. Research indicates that Coquitlam’s coastal climate makes regular maintenance 30% more critical than inland locations due to these accelerated wear patterns.

The financial implications extend far beyond simple repair costs, encompassing energy efficiency losses, premature replacement expenses, and potential property damage from water leaks and electrical failures. Understanding which appliances are most vulnerable during our wet season and implementing targeted protection strategies can literally save thousands of dollars while extending equipment life by years rather than months. The key is recognizing that Vancouver’s construction environment requires a completely different approach to appliance care than what manufacturers recommend for normal conditions.

Key Outtakes

- Vancouver’s coastal humidity reduces appliance lifespan by 20-40% compared to interior locations due to salt air corrosion and moisture damage

- Dryers are the number one casualty during BC’s wet season, running 50% more frequently than in drier climates and experiencing accelerated component wear

- Proper moisture protection strategies can extend appliance life by 3-5 years while preventing 80% of humidity-related failures

- Professional maintenance during optimal seasonal windows can reduce repair costs by up to 75% compared to reactive approaches

- Smart monitoring systems and targeted protection measures represent cost-effective investments compared to emergency repairs and premature replacements

Understanding BC’s Wet Season Impact on Appliance Performance

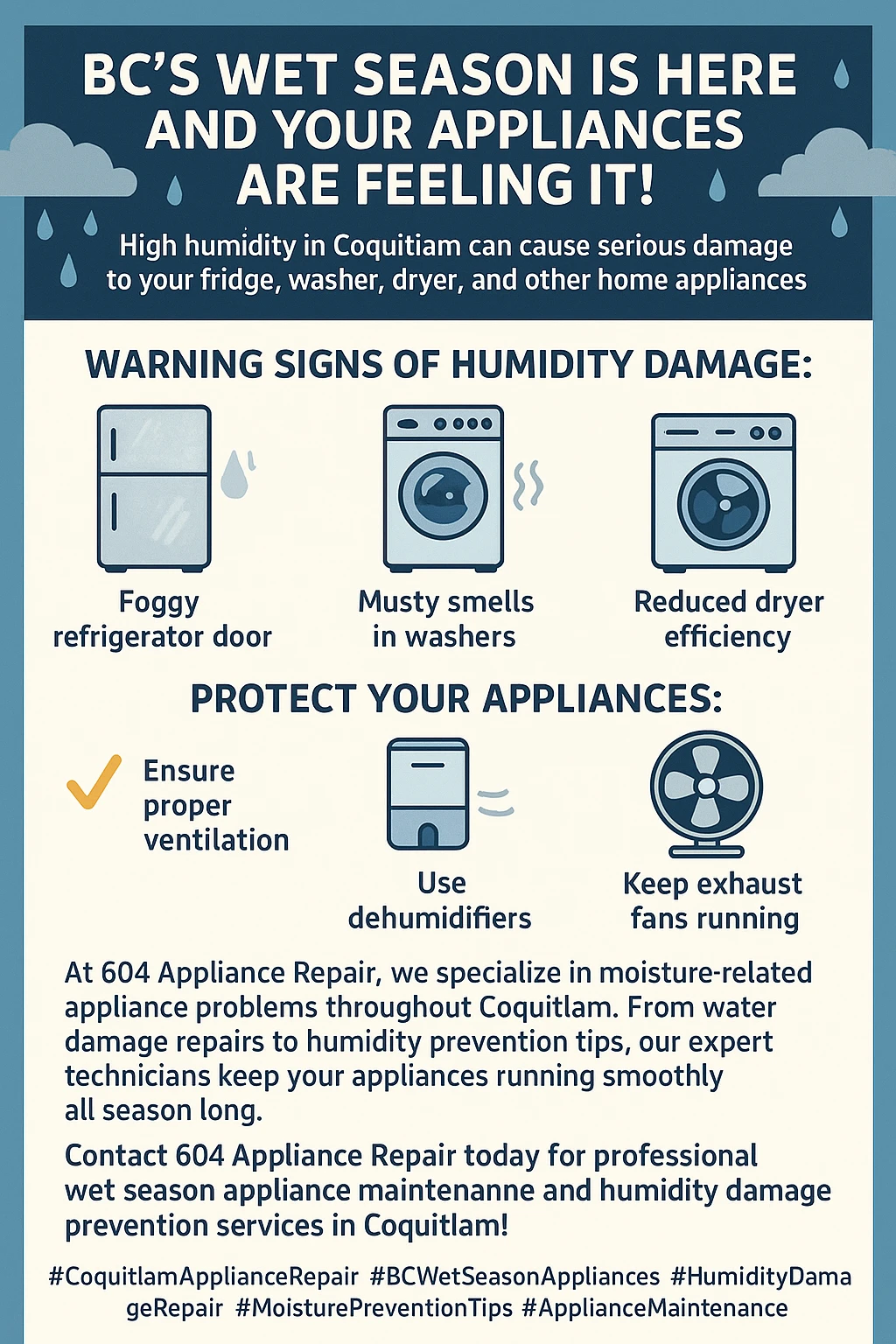

BC’s wet season creates a perfect storm of environmental conditions that systematically attack your household appliances through multiple interconnected mechanisms. The province’s extended rainy period, stretching from October through April, maintains indoor humidity levels far exceeding manufacturer design specifications for most equipment. During peak wet season months, indoor relative humidity frequently climbs above 60% even in well-ventilated homes, forcing cooling appliances to work significantly harder while simultaneously exposing them to moisture levels that promote corrosion and electrical failures.

The temperature fluctuations characteristic of our coastal climate create thermal stress cycles that are particularly damaging to appliance seals and gaskets. Unlike regions with stable seasonal patterns, BC experiences frequent transitions between near-freezing temperatures and mild conditions, sometimes within a single day. These thermal cycling events cause repeated expansion and contraction of rubber seals, plastic components, and metal housings, leading to the development of micro-cracks and seal failures that compromise appliance integrity over time.

Salt air penetration represents another critical factor that distinguishes our region from other humid climates. Coastal winds carry salt particles surprising distances inland, reaching homes throughout Coquitlam, Burnaby, and Surrey where they settle into appliance components and initiate aggressive corrosion processes. This salt contamination doesn’t just affect surface components – it penetrates into electrical connections, corrodes heating elements, and breaks down protective coatings from the inside out, creating failure patterns that can mystify homeowners and repair technicians unfamiliar with coastal climate challenges.

The combination of these environmental stressors explains why appliances in our region often experience premature failures that seem unrelated to normal wear patterns. What appears to be a simple mechanical breakdown is often the result of months or years of moisture infiltration, salt corrosion, and thermal stress working together to weaken components until catastrophic failure occurs. Professional maintenance can prevent 80% of summer breakdowns when implemented strategically during optimal seasonal windows.

The Seven Most Vulnerable Appliances During Wet Season

Analysis of repair data from across the Lower Mainland reveals that certain appliances demonstrate exceptional vulnerability to BC’s wet season conditions, with failure patterns that homeowners can learn to anticipate and prevent. Understanding which equipment faces the greatest risk allows you to prioritize protection efforts and budget appropriately for potential issues before emergency situations arise.

Dryers emerge as the clear leader in wet season casualties due to their constant battle against moisture during our extended rainy periods. These hardworking machines face increased usage demands as families struggle with constantly damp clothing and inadequate natural drying conditions. The combination of 50% more frequent operation and Vancouver’s elevated humidity levels forces dryers to work significantly harder to remove moisture, leading to accelerated wear on heating elements, motors, and electronic control systems. Vent condensation becomes particularly problematic when warm dryer air meets cold exterior temperatures, creating blockages that force equipment to work overtime while potentially creating fire hazards.

Washing machines, particularly front-loading models, represent the second most vulnerable category due to their design characteristics and exposure patterns. The horizontal drum configuration and rubber door seals create perfect conditions for salt residue accumulation and mold growth in our humid climate. High humidity levels promote mold and mildew growth in moisture-handling appliances, often causing seal failures and persistent odor issues that make equipment unpleasant to use long before mechanical failure occurs.

Refrigerators and freezers face unique challenges as they work overtime to maintain proper temperatures against elevated ambient humidity. When moisture levels exceed optimal ranges, cooling systems must work significantly harder to remove water vapor from interior compartments, dramatically increasing energy consumption while accelerating compressor wear. Salt air infiltration affects condenser coils, reducing heat exchange efficiency and forcing systems to run almost continuously during peak humidity periods.

Dishwashers experience accelerated failure rates due to their exposure to both internal moisture loads and external humidity infiltration. The combination of hot wash cycles and cool ambient temperatures creates ideal condensation conditions within appliance housings, leading to electrical component failures and accelerated corrosion of metal parts. Door seals and internal spray mechanisms prove particularly vulnerable to salt accumulation and mineral deposits that can compromise cleaning performance while promoting bacterial growth.

Microwave ovens and small kitchen appliances demonstrate surprising vulnerability despite their apparent simplicity. Electronic control systems in these units often lack the robust moisture protection found in larger appliances, making them susceptible to electrical failures when humidity exceeds design specifications. The constant temperature fluctuations during wet season months put additional strain on control boards and sensors, leading to mysterious operational problems that can be difficult to diagnose.

Effective Moisture Prevention and Protection Strategies

Implementing comprehensive moisture protection requires understanding that BC’s coastal conditions demand maintenance approaches significantly different from manufacturer recommendations designed for average climates. Successful prevention strategies address both environmental control measures and targeted appliance protection protocols that work together to create optimal operating conditions year-round.

Environmental humidity management forms the foundation of effective appliance protection, with whole-house dehumidification systems representing the most comprehensive solution for maintaining optimal moisture levels. These systems work continuously during wet season months to maintain humidity within the 30-50% range recommended for appliance longevity, while simultaneously reducing the workload on individual pieces of equipment. Advanced systems include integrated air filtration capabilities that remove salt particles before they can reach sensitive components.

Ventilation improvements specifically targeting appliance areas can dramatically reduce moisture accumulation around vulnerable equipment. Humidity management becomes critical in utility rooms during Vancouver’s wet season