The Best Time to Schedule Appliance Maintenance: A Coquitlam Homeowner’s Seasonal Calendar for Preventing Expensive Repairs

Tired of getting hit with surprise appliance repair bills that could’ve been prevented? Wondering if there’s actually a “best” time to schedule maintenance that’ll save you the most money and headaches in the long run?Let me paint you a picture that’s probably all too familiar. It’s the middle of July, you’re hosting a barbecue for your friends, and suddenly your fridge decides to call it quits. The repair technician quotes you $400 for a compressor issue that could’ve been caught during a $150 spring maintenance check. Sound familiar? As someone who’s been through the appliance repair roller coaster more times than I’d like to admit, I’ve learned that timing really is everything when it comes to appliance maintenance.  Living in Coquitlam, we deal with unique challenges that most maintenance guides don’t even mention. Our coastal climate means salt air is constantly working against us, humidity levels fluctuate like crazy, and let’s not even talk about what those sudden temperature swings do to our poor appliances. The good news? Once you understand how to work with the seasons instead of against them, you can literally cut your appliance repair costs in half while keeping everything running like a dream.The research I’ve dug into shows some pretty mind-blowing statistics. Strategic seasonal maintenance can reduce your repair costs by up to 75% while extending your appliances’ lifespan significantly. We’re talking about annual maintenance costs of $200-$500 that can prevent single repairs ranging from $100-$400, with major issues like compressor replacements hitting $800-$1,500. When you break it down like that, preventive maintenance isn’t just smart – it’s basically free money.

Living in Coquitlam, we deal with unique challenges that most maintenance guides don’t even mention. Our coastal climate means salt air is constantly working against us, humidity levels fluctuate like crazy, and let’s not even talk about what those sudden temperature swings do to our poor appliances. The good news? Once you understand how to work with the seasons instead of against them, you can literally cut your appliance repair costs in half while keeping everything running like a dream.The research I’ve dug into shows some pretty mind-blowing statistics. Strategic seasonal maintenance can reduce your repair costs by up to 75% while extending your appliances’ lifespan significantly. We’re talking about annual maintenance costs of $200-$500 that can prevent single repairs ranging from $100-$400, with major issues like compressor replacements hitting $800-$1,500. When you break it down like that, preventive maintenance isn’t just smart – it’s basically free money.

Key Outtakes:

- Spring and fall offer optimal maintenance windows due to transitional weather patterns and moderate appliance usage, allowing thorough inspections before peak demand seasons

- Monthly maintenance tasks like filter changes and basic cleaning prevent 80% of common appliance failures while requiring minimal time investment

- Professional annual inspections cost $200-$500 but typically prevent major repairs averaging $300-$800 in the Vancouver market

- Coquitlam’s coastal climate makes regular maintenance 30% more critical than inland locations due to salt air corrosion and humidity effects

- Appliances under 10 years old show the highest return on maintenance investment, with repair prevention typically costing 50-70% less than replacement

Understanding Coquitlam’s Climate Impact on Appliance Longevity

Here’s something most homeowners don’t realize until it’s too late – our beautiful coastal location comes with hidden costs for our appliances. The same salt air that gives us those gorgeous sunset views is quietly wreaking havoc on the metal components inside your machines. I learned this the hard way when my three-year-old dishwasher started showing rust spots that my inland friends had never seen on appliances twice as old.  The Lower Mainland’s humidity levels create the perfect storm for appliance stress. During summer months, your cooling systems are working overtime while kitchen appliances struggle against the ambient heat. Winter brings a completely different set of challenges as heating systems run constantly and water-based appliances face the risk of freezing during those unexpected cold snaps. This constant environmental stress means our appliances need more frequent attention than standard maintenance guides suggest.What really gets me is how many people don’t know about our hard water conditions. Areas throughout the Lower Mainland, especially parts of Richmond and Burnaby, have particularly challenging water conditions that cause scale buildup in dishwashers, washing machines, and water heaters. This mineral buildup doesn’t just affect performance – it can cut an appliance’s lifespan in half if left unchecked.The corrosion factor is huge here in Coquitlam. Salt air doesn’t just affect the exterior of your appliances; it penetrates into electrical connections, corrodes heating elements, and breaks down seals faster than you’d expect. I’ve started implementing protective measures like ensuring proper ventilation around appliances and using specialized cleaners designed for coastal environments. These small adjustments have made a noticeable difference in how long my appliances last between services.Temperature fluctuations throughout the year put additional strain on appliance components. Your refrigerator works harder during hot summer days, your dryer struggles with humid air, and your washing machine faces mineral deposits from fluctuating water temperatures. Understanding these environmental factors helps explain why following a generic maintenance schedule isn’t enough – we need approaches tailored to our specific coastal conditions.

The Lower Mainland’s humidity levels create the perfect storm for appliance stress. During summer months, your cooling systems are working overtime while kitchen appliances struggle against the ambient heat. Winter brings a completely different set of challenges as heating systems run constantly and water-based appliances face the risk of freezing during those unexpected cold snaps. This constant environmental stress means our appliances need more frequent attention than standard maintenance guides suggest.What really gets me is how many people don’t know about our hard water conditions. Areas throughout the Lower Mainland, especially parts of Richmond and Burnaby, have particularly challenging water conditions that cause scale buildup in dishwashers, washing machines, and water heaters. This mineral buildup doesn’t just affect performance – it can cut an appliance’s lifespan in half if left unchecked.The corrosion factor is huge here in Coquitlam. Salt air doesn’t just affect the exterior of your appliances; it penetrates into electrical connections, corrodes heating elements, and breaks down seals faster than you’d expect. I’ve started implementing protective measures like ensuring proper ventilation around appliances and using specialized cleaners designed for coastal environments. These small adjustments have made a noticeable difference in how long my appliances last between services.Temperature fluctuations throughout the year put additional strain on appliance components. Your refrigerator works harder during hot summer days, your dryer struggles with humid air, and your washing machine faces mineral deposits from fluctuating water temperatures. Understanding these environmental factors helps explain why following a generic maintenance schedule isn’t enough – we need approaches tailored to our specific coastal conditions.

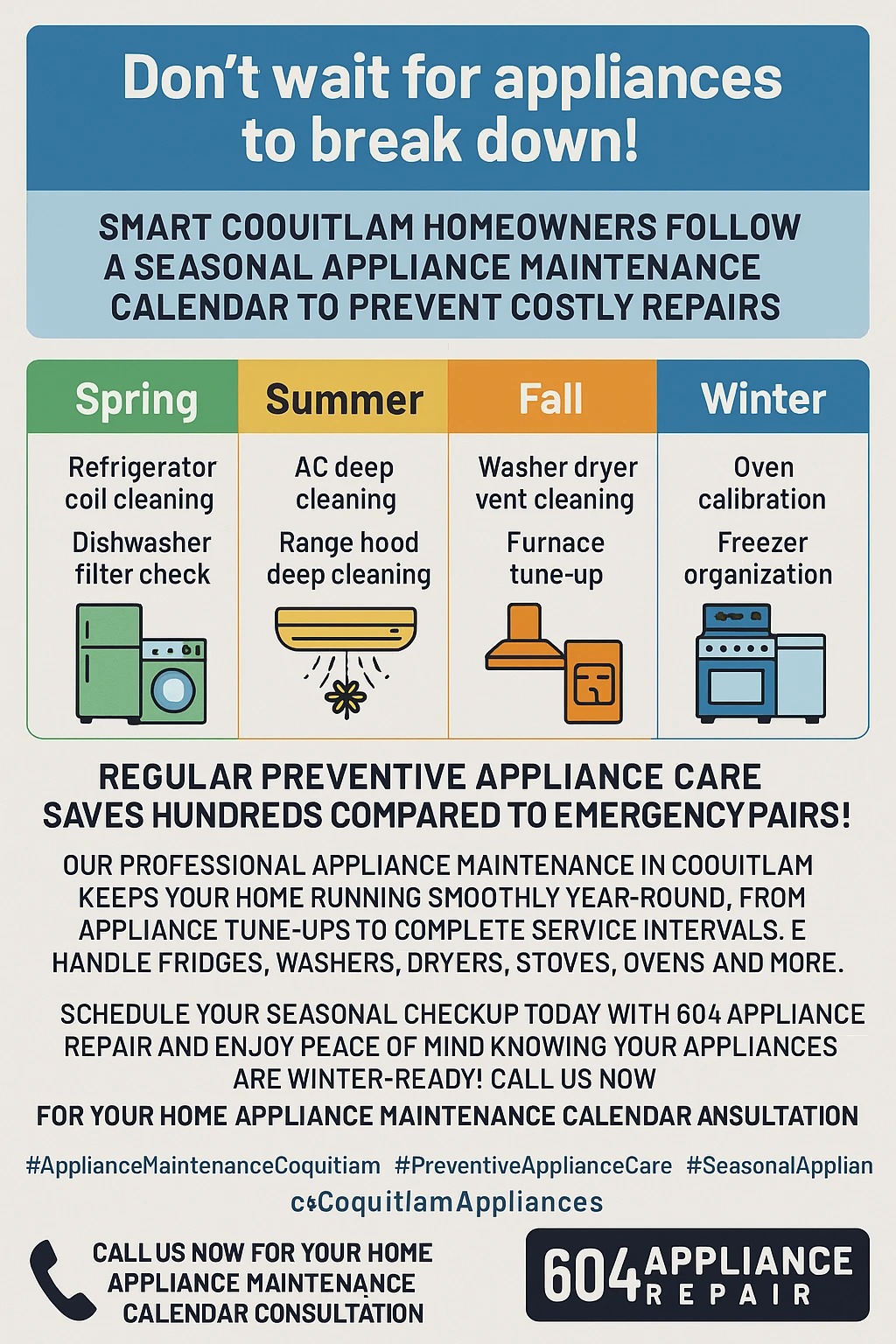

The Four-Season Appliance Maintenance Calendar

After years of trial and error, I’ve discovered that working with the seasons rather than against them makes all the difference in appliance maintenance. Each season brings unique opportunities to prepare your appliances for upcoming demands while addressing issues from the previous season’s wear and tear.  Spring represents the perfect reset opportunity for your entire home. This is when I focus on preparing cooling systems before the summer heat hits. Cleaning condenser coils on refrigerators and air conditioning units during mild spring weather enhances efficiency and prevents those expensive summer breakdowns. I’ve learned to inspect and clean dishwasher filters and spray arms thoroughly during spring cleaning – it’s amazing how much debris accumulates over winter months of increased usage.The spring maintenance window also provides ideal conditions for tackling outdoor appliance components. Cleaning exterior vents, checking connections, and removing winter debris sets everything up for optimal summer performance. This is when I replace any worn door seals that might have contracted during cold weather, ensuring proper insulation before cooling demands increase.Summer maintenance focuses heavily on cooling efficiency and kitchen appliance support. During peak usage months, I clean or replace air conditioner filters monthly rather than quarterly – the investment in filters pays for itself through energy savings. Kitchen appliances need extra attention during summer since they’re fighting against ambient heat while working harder to maintain proper temperatures.This is also the season when I schedule professional inspections for cooling systems before they face their heaviest workload. A technician catching a worn compressor belt in June can prevent a complete system failure during a heat wave. The key is timing these services during early summer rather than waiting until systems are under peak stress.Fall preparation has become my favorite maintenance season because it’s when everything comes together. This is prime time for deep cleaning and comprehensive maintenance that prepares appliances for increased winter usage. Heating systems need thorough inspection and cleaning before constant operation begins, while kitchen appliances require preparation for holiday cooking marathons.I use fall as my major appliance audit period, checking for any wear patterns that developed during summer and addressing them before winter stress compounds the issues. This includes checking all hoses for flexibility (cold weather makes rubber brittle), testing heating elements, and ensuring proper insulation around water lines.Winter maintenance shifts focus to protection and efficiency optimization. Home appliances work harder during winter months with heating systems running constantly and water heaters facing increased demand. Rather than major interventions, winter maintenance involves monitoring performance, maintaining proper airflow around appliances, and addressing any issues quickly before they compound.The key insight I’ve gained is that preventive winter maintenance often involves environmental controls – ensuring proper humidity levels, maintaining consistent temperatures, and protecting appliances from freeze-thaw cycles that can damage internal components.

Spring represents the perfect reset opportunity for your entire home. This is when I focus on preparing cooling systems before the summer heat hits. Cleaning condenser coils on refrigerators and air conditioning units during mild spring weather enhances efficiency and prevents those expensive summer breakdowns. I’ve learned to inspect and clean dishwasher filters and spray arms thoroughly during spring cleaning – it’s amazing how much debris accumulates over winter months of increased usage.The spring maintenance window also provides ideal conditions for tackling outdoor appliance components. Cleaning exterior vents, checking connections, and removing winter debris sets everything up for optimal summer performance. This is when I replace any worn door seals that might have contracted during cold weather, ensuring proper insulation before cooling demands increase.Summer maintenance focuses heavily on cooling efficiency and kitchen appliance support. During peak usage months, I clean or replace air conditioner filters monthly rather than quarterly – the investment in filters pays for itself through energy savings. Kitchen appliances need extra attention during summer since they’re fighting against ambient heat while working harder to maintain proper temperatures.This is also the season when I schedule professional inspections for cooling systems before they face their heaviest workload. A technician catching a worn compressor belt in June can prevent a complete system failure during a heat wave. The key is timing these services during early summer rather than waiting until systems are under peak stress.Fall preparation has become my favorite maintenance season because it’s when everything comes together. This is prime time for deep cleaning and comprehensive maintenance that prepares appliances for increased winter usage. Heating systems need thorough inspection and cleaning before constant operation begins, while kitchen appliances require preparation for holiday cooking marathons.I use fall as my major appliance audit period, checking for any wear patterns that developed during summer and addressing them before winter stress compounds the issues. This includes checking all hoses for flexibility (cold weather makes rubber brittle), testing heating elements, and ensuring proper insulation around water lines.Winter maintenance shifts focus to protection and efficiency optimization. Home appliances work harder during winter months with heating systems running constantly and water heaters facing increased demand. Rather than major interventions, winter maintenance involves monitoring performance, maintaining proper airflow around appliances, and addressing any issues quickly before they compound.The key insight I’ve gained is that preventive winter maintenance often involves environmental controls – ensuring proper humidity levels, maintaining consistent temperatures, and protecting appliances from freeze-thaw cycles that can damage internal components.

Appliance-Specific Maintenance Schedules and Intervals

Different appliances have dramatically different maintenance needs, and understanding these specific requirements has saved me thousands in unnecessary service calls. I’ve learned that one-size-fits-all maintenance schedules simply don’t work – each appliance type operates under different stresses and requires tailored attention intervals.Refrigerators demand the most consistent attention since they run 24/7 and any efficiency loss immediately impacts both food safety and energy bills. Professional service every 6-12 months focuses on cleaning condenser coils, checking refrigerant levels, and testing temperature controls. Between professional visits, I clean coils quarterly and replace water filters every six months – tasks that take minutes but prevent major issues.The refrigerator’s door seals get my attention quarterly since our humidity causes them to lose elasticity faster than in drier climates. A failing door seal can increase energy costs by 25% while forcing the compressor to work harder, leading to premature failure. I’ve learned to test seals by closing a dollar bill in the door – if it slides out easily, it’s time for replacement.HVAC systems require bi-annual professional attention, but the timing matters more than most people realize. I schedule spring service before cooling season begins and fall service before heating demands increase. This timing allows technicians to catch worn components before they fail under peak load conditions. Between